Here is a most ancient and despised bug in Archicad's wall cleanup behavior.

In most cases, if two surface edges meet whose materials are the same, the line between the surfaces is eliminated.

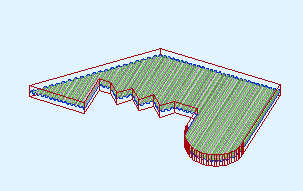

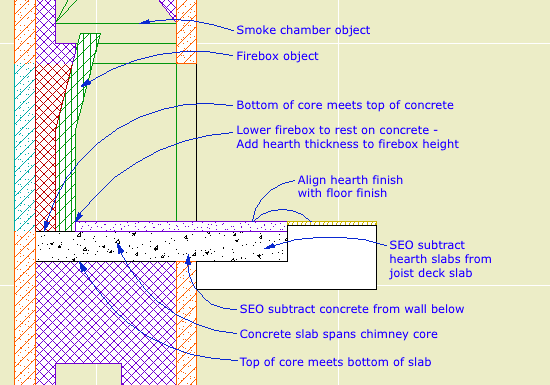

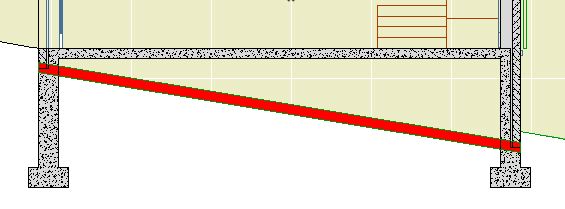

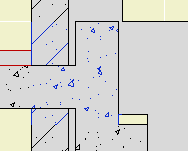

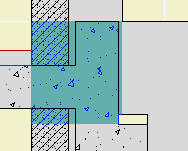

In our true masonry fireplaces, the hearth support is usually a cantilevered concrete slab. The hearth itself is a separate slab with its top at the level of the finish floor, usually 3/4" above story zero.

This finish slab may vary in thickness, and will often be thicker than the typical finish floor. You want to see this slab in plan; put it on A Fireplace or A Cabs2. The concrete slab will be placed directly below the finish slab. It should go on A Chimney3.

Modeling the hearth structure tends to be a construction documents phase task. When you began modeling the chimney in schematics and/or design development, you might have placed the firebox object at project zero, which was OK then. Once you have the real hearth structure in place, however, you need to lower the firebox to meet the structural slab, not the finish hearth. Make sure you add this adjustment to the height of the firebox object, so the top stays put. The polygon wall surrounding the firebox object also needs to be stretched down to meet the slab. (The wall height can be stretched in section, not so much for the object. LAME.)

The structural slab usually extends all the way through the chimney stack. The core portion of the chimney below should be shortened to meet the bottom of the slab.

The other clashes between the hearth slabs and surrounding elements are solved with solid element operations. Both hearth slabs need to be subtracted from the main joist deck, and the concrete slab may need to be subtracted from the non-core wall below.

To be clear, don't move the joist deck to accommodate the hearth; you need it where it is to complete the ceiling of the story below. But the finish floor should be edited to go around the finish hearth. If there's a floor finish fill, it needs to go around too.

Hearth flush with finish floor

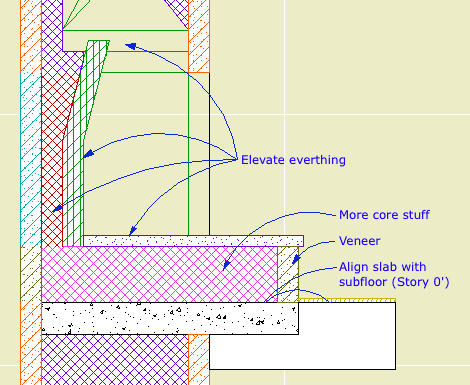

A raised hearth is not much different. The concrete slab will usually be at the level of the joist deck. The finish hearth, the firebox parts, the smoke chamber, and the flue are all raised by whatever distance. You need another slab of core-type stuff, probably CMU, on top of the concrete slab. The front surface of the hearth will be some sort of veneer material, consisting of walls on the A Chimney3 layer.

Raised hearth

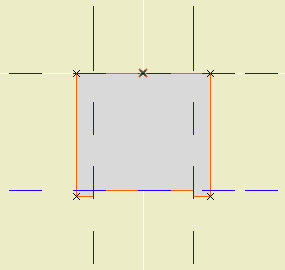

Chimney/Fireplace 1: Fireplace in Plan

Chimney/Fireplace 2: Chimney in Plan and 3D

Chimney/Fireplace 3: Flues

Chimney/Fireplace 5: Chimney Top JM11

Not for Construction

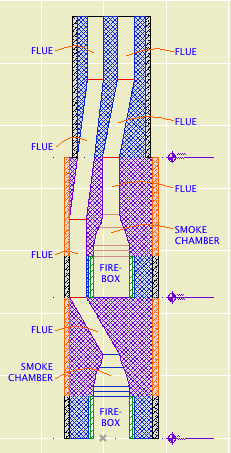

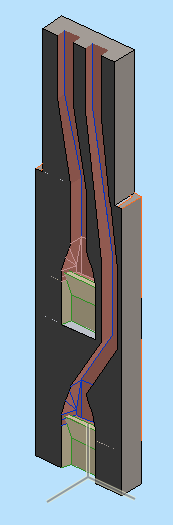

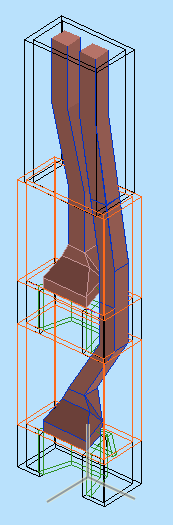

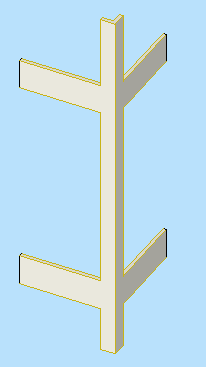

The path of the smoke inside the chimney is created by a series of SEO subtractions using the Smoke Chamber and Flue objects as operators. The targets are whatever elements the objects pass though.

Each firebox has a smoke chamber directly on top of it.

Directly on top of that is a flue object. In a simple chimney where the flue goes straight up, that might be the only one you need. Usually, however, you will need a chain of flue objects to accommodate bends in the flue. The bending is done by offsetting the top of the flue object.

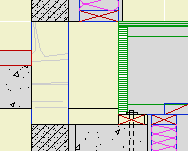

All the smoke chambers and flues should be on the layer A Flue. This layer shows in plan. The flue object has display controls so you can decide how much of a particular segment will show in plan. For a slanted segment, you can choose to show the 'X' at the top or bottom position of the segment. Don't forget about showing objects on stories above and below.

The smoke chamber should be drawn with a white pen such as 60 or 80. Make sure it isn't a thick white pen. (In the 11 templates this is #40.) The smoke chamber can show the 'X' in plan as well.

Like with any vertical modeling, you will find it very helpful to cut a couple of sections through the chimney to line up the flues top to bottom. But: The A Flue layer is set to wireframe by default. You won't see the flues in section unless you switch the layer to solid. The objects should use Air Space as their cut fill to differentiate them from the surrounding masonry material.

If you show this to a mason he will have a good laugh, but it does allow you to schematically design the chimney and determine if you have enough space for the flues to fit while maintaining allowable slopes. (Which, right, that one piece looks a little stressed.)

Related:

Chimney/Fireplace 1: Fireplace in Plan

Chimney/Fireplace 2: Chimney in Plan and 3D

Chimney/Fireplace 4: Hearth Structure

Chimney/Fireplace 5: Chimney Top JM11

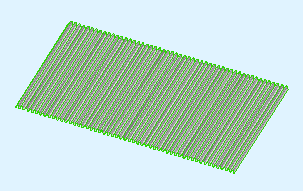

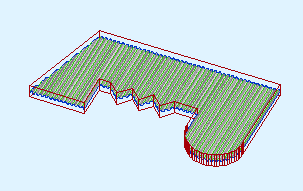

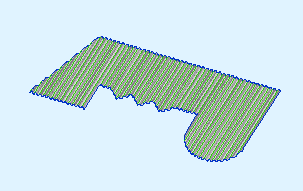

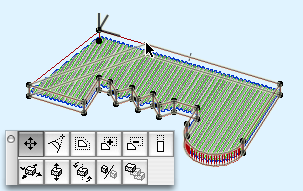

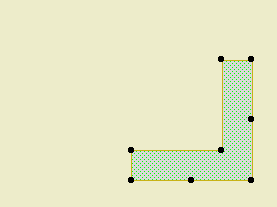

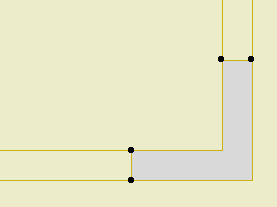

As you know, you don't cut the grade mesh using the building elements. You place slabs in the shape of the holes you need to fit the building.

You might find cases where it's more appropriate to use a roof:

Create the roof with the pivot line at one edge. Go to a section and fix the slope graphically, using the slope button.

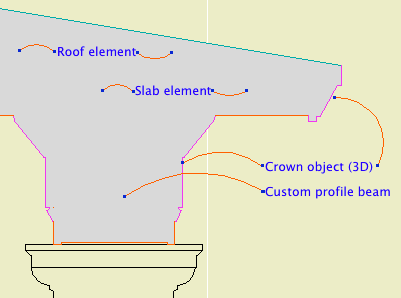

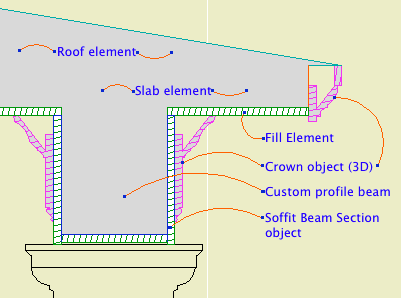

Here's the ordinary elements by themselves. I put in some detail objects for clarity:

The top of the concrete wall is in the right place for the joists, but it's part of a composite with the stone veneer that needs to reach the bottom of the slab. Likewise, the frame part of the upper composite is right, but the stone needs to come down.

There are several ways to solve this with walls and slabs. I'm not going to go into them, except to say they are all rather unpleasant, typically involving 3-5 elements, some of which will be new composites. Sad work, especially when you have to take the whole mess around a corner.

An alternative would be to use fewer elements, get it looking OK-but-not-great, and then use a patch to make it pretty. As you know, you create a patch from existing geometry, and then use 2D editing to force it to look right.

(To be clear, I'm not against patches. They are hacks, but often essential hacks.)

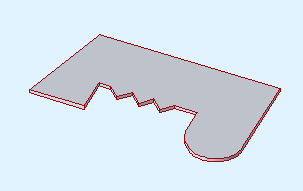

Here's the thing though: If you're going to push fills around to make the condition look right, why not do it in a custom profile? It's still a 2D shortcut, but you end up with a 3D piece you can use wherever you find the condition. It will miter around corners and generally behave like a proper modeling element, displaying correctly no matter where you view it.

A custom profile can be arbitrarily complex, made up of any fills in any shape, and when it's placed it will clean up in section to the like fills it touches. Its surfaces will clean up to like surfaces in elevation.

Such a profile could used with a wall or a beam element. Use a 3D-only layer such as A Wall3. It's probably easier to place the wall/beam on the lower story in this case. If you use a wall for the profile, set its Floor Plan Display to 'Overhead All' so it stays transparent.

Conclusion: If you're facing a multi-fill section patch, see if you could use similar fills in a custom profile instead.

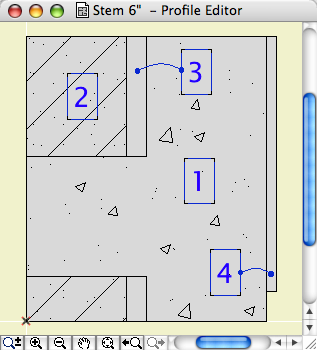

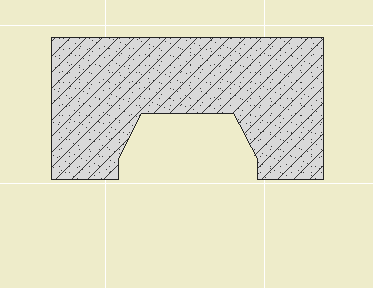

(1) A custom profile for modeling and (2) an object for annotation.

Profile:

In the profile editor

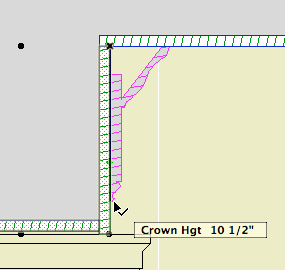

• The horizontal stretch extents are inside the fascia board reveals. This way, when you adjust the overall width the fascia thickness will be unchanged. Similarly, the vertical stretch extents go from the top to the underside of the soffit, leaving out the reveal.

The custom profile tech only allows you to stretch one dimension horizontally and one vertically. You can exempt parts of the profile from stretching, but you can't stretch them independently. If you want a different reveal depth or fascia thickness, you'll need another profile.

• Profiles can stretched bigger, but not smaller. (I call this a bug, but what do I know.) Any profile you intend to use with varying dimensions needs to match or be *smaller* than the smallest case you have.

• The templates have two profiles, Coffer Beam and Coffer Beam Half. Both are 4" x 2" which should be small enough. The half version has the fascia on only one side and is meant to be placed along a wall.

Remember that profiles are attributes, so they're within the project file, so you can edit them without messing up anybody else. And: You can use Attribute Manager to bring profiles into the current project from the templates.

Here is a sample condition at 1/4" scale, no detail added:

At higher scale, we need to add detail:

Object: Soffit Beam Section JM10

Location: 06 Wood & Plastic / 2D Wood

The object fits within the profile's perimeter.

• Height and width of the object will match that of the beam itself.

• Parameters for Fascia thickness and reveal.

• Crown Hgt sets the point at which the pen switches from the object's cut pen to the Separator Pen. In practice this height should meet the bottom of a crown object placed against the beam, which will maintain the heavy outline.

• The Half option uses one fascia board to work with the half version of the profile.

Commentary:

We build one model. We take views of the model and annotate them as needed. We will take views of the model at various scales. Scale is fundamental to architectural documentation: As we look closer, we see more.

Yet Archicad lacks any meaningful automatic scale sensitivity, except that written into objects by people who want it such as me.

In this example, see how the crown objects draw themselves as empty blobby things at 1/4" scale, but they're detailed shapes with proper fills at higher scales. The roof, slab, and beam elements, not so much. (Archicad library objects, not so much either.)

Since we can't get conventional AC elements to detail themselves according to scale (yet, I hope I hope), we need to build a model that can accommodate the detail we need to add. This is the idea behind something like the Stud Wall Detail object. The wall is empty, and we place the object in the viewpoints that need it.

The soffit detail described here has always been tricky. If you approximate the beam with a rectangular model, it's difficult to manage the reveal without masking. It's easier to add 2D detail than to subtract modeling.

A custom profile allows us to handle the cased beam in the "Empty Fill +" fashion we are accustomed to with walls, roofs, and floor decks.

Prettier version from AC20 here.

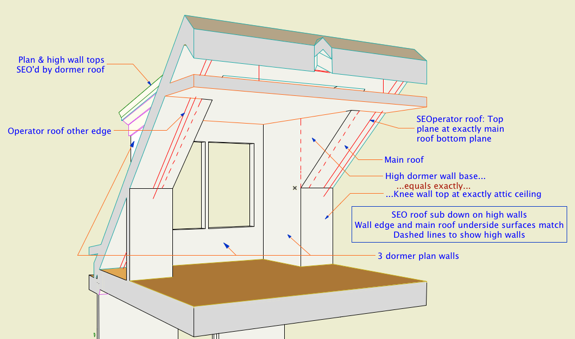

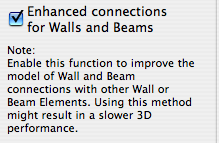

Attic dormers have long been a black art in AC modeling. The 3D cleanup improvements in AC10 make their behavior much more predictable. In order to see these improvements, make sure this box is checked in Preferences -> Construction Elements:

I can't say I've observed a performance hit in using this. No matter, it needs to be on.

About 60-80% of this post is missing.

This is a complicated topic. No, it's not a complicated topic, it leads to complicated topics. If I can decide how to limit the discussion, it isn't complicated at all. This is the dilemma with a lot of powerful AC features. I'd like you to grasp the whole puzzling, quirky thing, but I'd also like you to get your work done. I can't decide whether to make you work for it or just give you the answer.

Well, the Floor plan cut plane is way over on the quirk end of the curve, so it's easy to decide this time: Here's the answer. I'm leaving out a lot. UPDATE: Here's more if you want it.

So. Roofs in Plan.

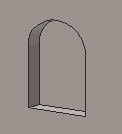

A rectangular or arched shape for subtracting niches into walls.

If the Arch Height is zero, the top is flat. The Wall Pen draws a heavy line around the back of the niche, to match the weight of the wall's contour.

The side with the center node should go along the edge of the wall. That side is drawn with the object's pen.

The idea is to SEO subtract the object from the wall, as discussed here. You can use a window to cut a niche, but the subtraction gives you better display control.

You would typically place the object on the layer X SEO Show2. This is the layer for SEO operators that show in plan only. (In 3D views, you would see the niche, but not the operator itself.)

You might need to bring the object forward to make sure it masks the wall. The parameter Edge Nudge helps make sure the lighter edge line of the object covers the heavier wall contour line underneath. Turn on True Line Weights to check it, and increase the nudge as needed.

Download (AC10)

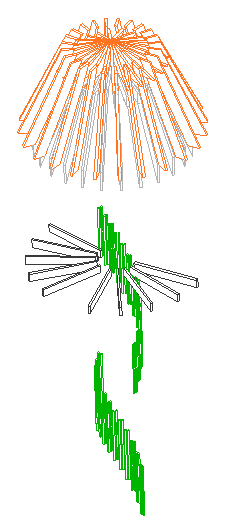

Kinda looks like a jellyfish

By themselves, it's not a lot of elements, or even a lot of polygons.

Yet these guys were found to be the cause of a severe and mysterious performance problem. An elevation containing the tower, which should generate in about 30 seconds, took four minutes to generate with these elements in the model.

The problem: AC has to figure out what's in front of what behind what in front of what, for all those overlapping elements. The calculations quickly become very complex and it takes time.

Here's the tricky part: The columns and objects weren't even visible in the elevation; they weren't going to be drawn at all. But apparently there's no way for AC to know that in advance, so you have to wait an extra 2-4 minutes for every section/elevation to generate.

It was hard to figure out, which took some time, but I'm afraid to wonder how much time was wasted over the weeks since those elements were put in.

BTW, it's not my project.

How I figured it out. I tried tearing out all the old objects, resolving the intermittent report errors, doing a forward merge, and opening the project as a dummy user, none of which worked.

There was a clue in the progress dialog as the elevations generated, but it took me a while to recognize it as such. The progress bar would hang up on 'Processing Objects' and 'Processing Columns'. The objects clue isn't much of a clue; of course there's a lot of objects. Hanging on columns is weirder, so weird that I figured it was a glitch; that was a mistake.

I still suspected mystical corruption, and it's my superstitious belief that corruption develops over time, so I tried deleting the whole first phase of the model, which is not in the current scope of work. (I used a heavy marquee for this.) That worked. I undid the delete.

Then I noticed the tower. I thought such a contraption probably has some funky geometry. I deleted the tower only, and that worked. Then I switched to the thin marquee and tried deleting one story at a time. This was disappointingly ineffective. Now I know that the reason is that the complexity was spread over several stories.

But when I trashed the top story, with all the beam objects, the 'Processing Objects' delay went away, leaving only the 'Columns' delay. I finally realize that the progress dialog wasn't totally off base. If losing objects helps, then we should look for some columns to lose. I did a select-all-columns within the marquee on each story, which finally coughed up the balusters.

Delete. End of slowness.

Tips:

• If you've ruled out file corruption, you need to look for 'heavy' conditions in the model itself.

• If you just did some weird complex modeling and suddenly it slows down, that's a big hint.

• You can tear the model in half and throw it away. Undo is your friend. Saving as is your friend. Start trashing stuff and see if the problem goes away. You can do a similar test by turning off half the layers, then the other half, etc.

• Watch the progress dialog. If it spends a long time on 'Objects' or 'Columns' or whatever, or the time estimate shoots up at a certain stage, that's a clue.

I thought we were supposed to model everything.

This is a good time to review this. We don't 'model everything'. We model what it is efficient to model, which, for a skilled ACer, is a lot of stuff. You model the major pieces of the project. You model stuff that shows up in a lot of views. You model enough to really understand the building. You model enough that annotations can be added easily.

You have to work within your own abilities and within the power of AC on your machine.

I hope it's obvious that you don't model things that cause AC to bog down and start wasting your time. We don't model joists, individual rafters, or other generic framing. Too much work for us, and, it turns out, for AC.

In the tower, some of the framing was intended to be exposed, but most of it was 'architecturally' insignificant and should have been skipped. The balusters are definitely nice to model, but there are situations where you need to compromise to keep the model running smoothly.

Maybe the tower section should be a drawing, or maybe a drawing elevation of the balusters should be pasted into the model SE window. Maybe the balusters should be on a layer that only shows in 3D views and not in section/elevation. That kind of lateral thinking.

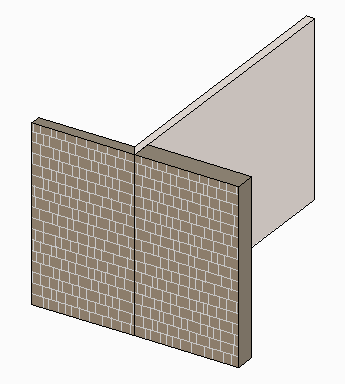

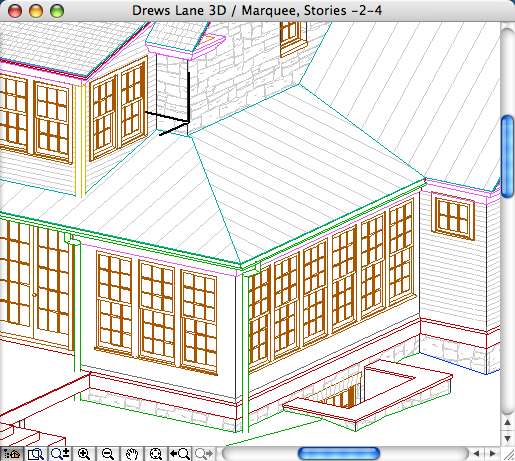

3D wall cleanup is substantially improved in AC10. It's still not perfect, but many more junctions that should cleanup actually do.

Example: This tip should be workable in AC9, but it just doesn't clean up. In 10 it does, so here goes.

Instead of using a cornerboard object, use a polygon wall. Use one wall for all the stories. That is, the base is perhaps somewhere around zero and the top is up around 20'. Set the Show on to 'Automatic' and the Floor Plan Display to 'Projected'.

If you have band boards, they should meet the ends of the polywall, rather than forming a corner themselves.

You can place as many band walls as you need, on whatever story, and they will all clean up. With the object, they don't.

The wall also has the advantage of being stretchable in section. Can't do that in 9 either. (As of the writing, there's a bug in 10 which prevents vertically stretching polywalls in 3D. That can't last.)

As long as I can remember, we've used a polygon wall for a fireplace, with a 3D-only wall or slab above to take the chimney to the ceiling. This method has been developed pretty far.

This new method isn't going to give you the 1" chimney section for CDs, but for schematics, it feels a little simpler.

This technique is for wainscot, or glazing areas where the trim of multiple window units runs together. Short version: a thin wall with empty openings. It's a good example of 'throw down and fix'. Here's the subject structure:

In the Archicad library, there are niche objects, such as W Niche and W Niche Round. These are actually windows. They are built on the WALLNICHE GDL statement. The trouble with these niches is that with the Doors & Windows display option set to Hide on Plan or Reflected Ceiling, they appear to be full, through-wall openings. In addition, they may not handle composite walls correctly.

This is fine:

But when you turn the Doors & Windows off, you get a misleading graphic:

Instead, try a slab and an SEO subtraction.

Start with a polygon wall in the shape of the firebox and chimney plan. The height should be the height of the firebox opening. The fill should be rubble, assuming stone veneer.

1 Stone polygon wall

Instead of cutting a hole all the way through the grade mesh, use slabs on the X Site Cutting layer to subtract material to the proper depth.

Place layout lines where you plan to split the wall.

Solid Element Operations allow you to modify the geometry of one element using the geometry of another. You can add volume, subtract volume, get the intersection of two volumes, or subtract upwards or downwards with a volume.

SEOs make several things that used to be hard easy (true roof thicknesses with nice eaves), and some things that used to be practically impossible possible (differing materials at a slab's perimeter and a hole).

As follows...

Here goes...

When you put a regular hole in a slab, the hole edge material is the same as the slab outer edge. This is a problem, since the slab can't clean up to walls of different materials. Using SEOs instead makes it possible to have a different material at a hole. The key is the option for new surfaces of target to 'inherit attributes of operator.'

Update: In AC10, they made some changes to wall cleanup that simplify this process quite a bit.

Yes. Perfect. If you're into that sort of thing. It takes some doing.